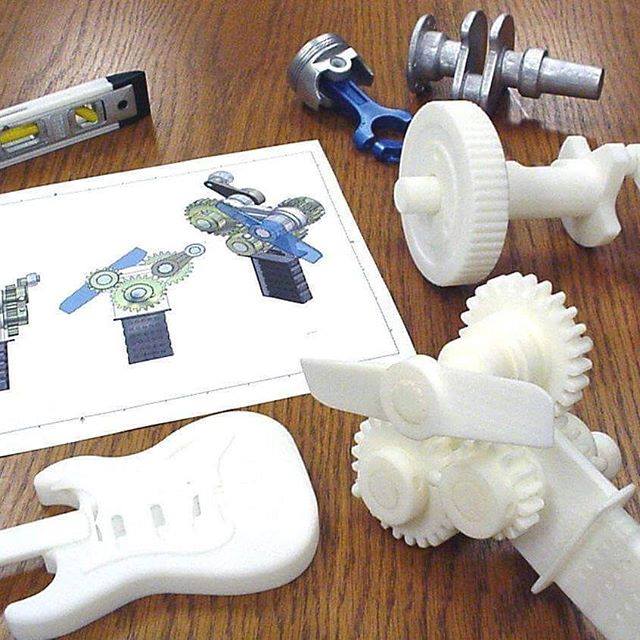

The innovative method of three-dimensional printing, where solid objects are churned out, layer by layer from the initially created digital file can help you to stay a step ahead of the rest, in the competition. You want a prototype to be made, and thereby, give shape to the idea that you have envisioned. Had you taken the help of the traditional method of manufacturing, you would have to wait for months, but now, within a few days, you can bring the idea to the market.

|

It facilitates cost cutting

Hence, it pays to have a 3d printing company near me. You can save not only your time but also your money. The additive process of manufacturing doesn’t require much investment. The rates are lower than the traditional process of machining. In the traditional processes of manufacturing and machining, you would have to use injection mold equipment. The process would have also required specialized prototyping tools, but if you have a scanner, computer, and three-dimensional modeling software, you can give shape to your idea in the form of a three-dimensional object.

You can get the design verified

It is far more costly to invest in the traditional machining tools than in scanners, three-dimensional modeling software, and scanners. So, now you realize Iannone3d which happens to be a 3d printing company near me can play an effective part in reducing your expense. You can get the design verified; find out if it has issues or defects by building a three-dimensional prototype which is production ready. It is advantageous to get the design verified, and if necessary rectified. After the verification has taken place, you can invest in the expensive machining tools. It is less expensive to bring about verifications in the three-dimensional printed parts than to redesign a part which has been made using the traditional method of machining.

You can communicate with the potential buyers

The three-dimensional process of product manufacturing is free from ambiguity. You can use your digital file to represent the conceptual picture. The printer, for that matter, the manufacturer knows the exact idea that you have in your mind. So, you can get the exact prototype, and get it ready for the market. Then, you can use that object for communicating with your prospective customers who also have a precise idea of the concept that you are giving shape to. Since the three-dimensional mode of product making facilitates the manufacture of prototypes, you can use those for communicating with your customers.

Facilitates custom designing

You can test the response of buyers to the product that you have envisioned. You can also access and evaluate the buyers’ response. Before gearing up for the production process, it pays to solicit the response of buyers. In that way, you can test if the product to be launched has potential. The three-dimensional process of product making facilitates personalization. Consequently, you can get the product tweaked and customized to suit your individual needs. You can lay your hands on the customized fits that play an effective part in the medical, dental and the fashion industries. With the help of these customized solutions, you can prove your point, and establish why you are different from the rest, in the market.

0 comments:

Post a Comment