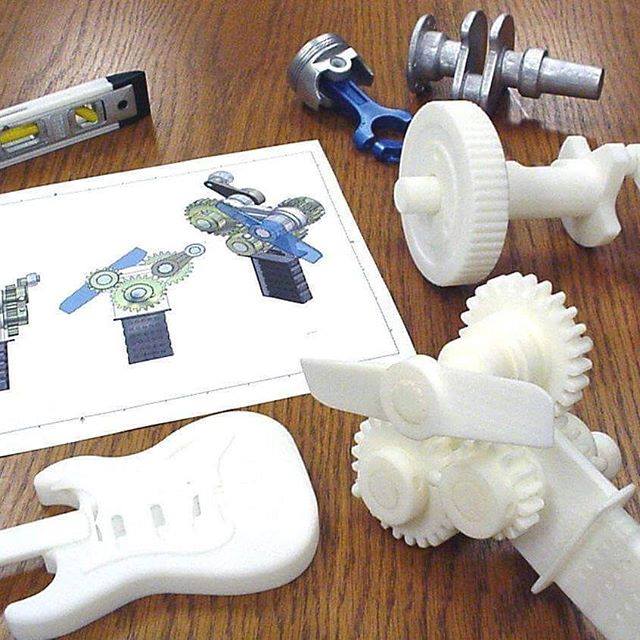

You need to sell your idea, to the market, but for doing that; you have to design a prototype. The prototype has to be introduced into the market, and after the introduction, you have to see the market’s response towards the same. Manufacturing prototype is a time-consuming process, especially, if you were to use the traditional method of molding and manufacturing. The other option lies in using the three-dimensional process of printing and manufacturing. The option is not only cheaper than the traditional method of prototype molding, but it also minimizes the wastage of time.

The best option

Instead, of investing in mold tools and the other expensive equipment, you can take the help of the 3d printing bureau Service. It can get the product printed and designed within the next twenty-four hours. In this way, it shrinks the process of development and thus, ensures that you stay well ahead of your competitors. Secondly, the three-dimensional process of printing is less expensive than the traditional model of machine designing. You can give rise to the same concept, at rates lower, than the usual. The fact that you can save money, as well as, time proves to be advantageous, from the viewpoint of your business.

Doesn’t require an inventory

You need not set up an inventory because the additive process of manufacturing produces parts in small lots. Hence, you can do away with the idea of maintaining an inventory. The stock cost or the inventory maintenance cost can be got rid of. The fact that you are producing goods in small quantities is enough to serve your commercial purposes. Iannone3d specializes as the 3d printing bureau service adds speed to the process of manufacturing. The facility knows how to make optimum use of the technology, where the maker can directly move from concept designing to getting the products finally printed for the market.

Some more beneficial features

The concept is such that you can dramatically minimize the cycle time. The prospect of three-dimensional designing and product making is free from the tooling process, and this makes, the process swifter than the traditional processes of product designing and manufacturing. You can create parts and spare parts, according to the demand of the market. The manufacturing process is a lot agiler than the traditional procedure of manufacturing, and this, in turn, helps you to simplify supply chains. The processing steps used are fewer than that used in the traditional process of manufacturing. Since you have less number of steps to use; you need not waste unnecessary time in assembling the product, or the parts associated with the same.

Contributes to profit making

The additive manufacturing process uses less energy than the traditional process of manufacturing. You can also use the process for controlling the generation of waste. So, now that you are aware of the advantageousness of the additive process of manufacturing, you can readily understand how the prospect can contribute to your growth and profitability. From minimizing the generation of waste to optimizing the use of energy, the three-dimensional printing and prototyping method can help you in ways, more than one.